Efort ER360-2800 is a highly mature "labor-intensive" industrial robot. It perfectly balances the four key factors of load, working range, precision and cost, making it an ideal choice for manufacturing enterprises to achieve automated production of heavy workpieces, reduce labor costs, and enhance production efficiency and safety.

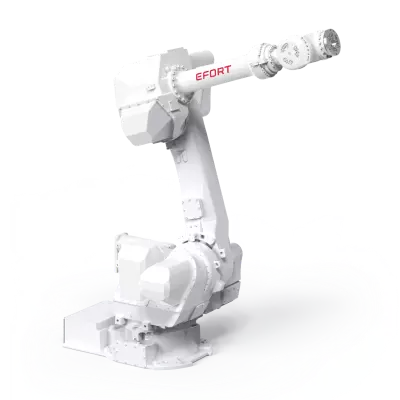

360kg EFORT Heavy-Duty Robot for Efficient Material Handling

EFORT NEW MODEL FOR 360 KG, Maxium payload 360 kg with maxium reach 2792 mm

- description

- Specifications

- Product structure diagram

-

description

Highlights

- With a repeat positioning accuracy of up to ±0.06 mm, it achieves world-class performance and meets the demands of high-precision applications.

- Its high-speed trajectory is smooth and shock-free, significantly optimizing cycle time and enabling highly efficient production.

- Supporting mainstream industrial fieldbus protocols and providing both an SDK and offline simulation software, it reduces integration complexity and shortens commissioning time.

Applications

The ER360-2800, with its features of high load capacity and wide operating range, is mainly applied in the following scenarios:

- Heavy-duty handling and palletizing: In industries such as building materials, chemicals, feed, food and beverages, it is used for the automated handling, stacking and depalletizing of heavy materials in bags, boxes, drums, etc.

- Machine tool loading and unloading: Serving large CNC machine tools, stamping machines, injection molding machines, etc., it realizes the automatic loading and unloading of heavy metal plates, molds, and workpieces.

- Casting and forging: In the casting industry, it is used for taking and placing high-temperature castings, and for subsequent treatments such as deburring and grinding (special protection is required).

- Automobiles and auto parts: Used for the handling, assembly and positioning of large components such as vehicle chassis and body.

It can be used in applications including welding, dispensing, assembly, loading/unloading, material handling, and palletizing.

Industries

Suitable for industries such as automotive, aerospace, lithium battery, photovoltaic, and logistics.

-

Specifications

Model ER360 - 2800 Type Articulated Controlled axes 6 Axes Max. payload on wrist 360 kg Repeatability ±0.06 mm Robot weight 1840 kg Reach 2792 mm Robot IP grade IP65 Cabinet IP grade IP54 Drive mode AC servo drive Installation Floor Installation enviroment Ambient temperature 0~45 ℃ Ambient humidity RH≤80%(No dew nor frost allowed) Vibration acceleration 4.9 m/ s²(<0 . 5 G) Allowable load moment at wrist J 4 2200 N ·m J 5 2200 N ·m J 6 1000 N ·m Allowable load inertia at wrist J 4 230 kg ·m ² J 5 230 kg ·m ² J 6 145 kg ·m ² Maximum speed J 1 110 °/ sec J 2 100 °/ sec J 3 100 °/ sec J 4 140 °/ sec J 5 110 °/ sec J 6 180 °/ sec Motion range J 1 ±185° J 2 +65 °/ - 85° J 3 +180 °/ - 70° J 4 ±360° J 5 ±130° J 6 ±360° -

Product structure diagram