All You Need to Know About Painting Robots

Release time: 2025-10-30

With the continuous development of industrial automation, painting robots have become an indispensable part of modern manufacturing. Whether in the automotive, home appliance, or aerospace industries, the application of painting robots has brought significant benefits to companies. Today, we will delve into painting robots, a highly efficient automation solution, to help you better understand their working principles, advantages, and applications across various industries.

Table of Contents

What Is a Painting Robot?

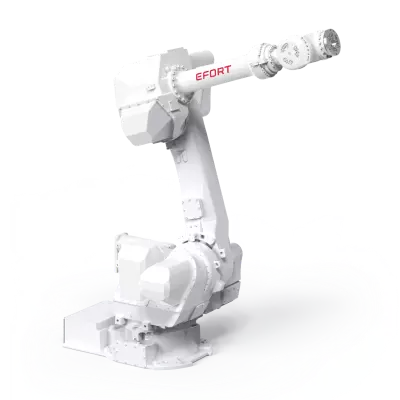

A painting robot is an industrial robot used for automating coating tasks, typically equipped with an adjustable spray gun, robotic arms, and advanced control systems. It performs precise spraying operations controlled by programming, completing complex coating tasks during the production process. Painting robots are widely used in industries that require detailed coating, and their primary task is to apply uniform layers of paint to product surfaces, improving production efficiency, reducing costs, and ensuring high quality.

How Does a Painting Robot Work?

The working principle of a painting robot is relatively simple but highly precise. First, the robot uses its control system to position the spray gun on the target surface and adjusts parameters like spray pressure, nozzle size, and spray angle according to the preset program. The robotic arm, equipped with high-precision sensors, ensures precise positioning, ensuring every layer of paint is applied evenly and without omission. Modern painting robots can not only perform single-color coatings but also handle multi-layer composite spraying tasks, meeting higher coating requirements.

Which Industries Benefit from Painting Robots?

Painting robots have found extensive applications in various industries. Below are some typical areas of application:

- Automotive Industry: Painting robots are used to provide uniform coatings for car bodies with high efficiency and quality. Due to the complex nature of automotive manufacturing and the high precision required for coating, painting robots solve the problems that manual painting cannot achieve, improving production line speed and consistency.

- Home Appliance Industry: Painting robots are widely used in the production of home appliances such as televisions, refrigerators, and air conditioners, providing high-quality exterior coatings. These robots not only reduce the drawbacks of manual painting but also improve material utilization and reduce paint waste.

- Aerospace: In the aerospace industry, painting robots are crucial for tasks such as coating aircraft exteriors and components with corrosion-resistant coatings. Their precise spraying technology effectively prevents issues like uneven coatings and bubbles, ensuring the uniformity and durability of the coatings.

- Construction Industry: Painting robots are used for coating large surfaces such as building exteriors, spraying paint, and other large-area tasks. This automation technology not only improves construction speed but also ensures the consistency and aesthetic quality of the coatings.

What Are the Advantages of Using Painting Robots?

Painting robots offer a range of significant advantages, including:

- Efficiency: Compared to traditional manual painting, painting robots dramatically increase production efficiency. The robots can maintain consistent paint quality during continuous work, reducing production cycles and increasing output.

- Precision: The robots can ensure even and accurate spraying through precise programming, avoiding the flaws and inconsistencies that may arise from manual operations. Whether it is the spray angle, coating thickness, or spray area, painting robots can control every aspect with high precision.

- Reduced Labor Costs: By using painting robots, companies can significantly lower labor costs, reduce the errors and inconsistencies of manual labor, and ensure the stability of the production process.

- Environmental and Safety Benefits: Traditional spray painting often results in the release of volatile organic compounds (VOCs) and other harmful gases. Painting robots, through their closed spraying systems, reduce the emission of these harmful gases, while also minimizing the health risks to workers.

- High Material Utilization: Painting robots apply paint with high precision, reducing waste and lowering production costs.

How Do You Choose the Right Painting Robot?

When selecting a painting robot, companies need to consider the following factors:

- Production Needs: Choose a robot based on the complexity of the coating task and the type of product. For high-precision and multi-layer coating requirements, robots with multi-axis motion and high control accuracy are essential.

- Working Environment: The installation location and working environment of the painting robot will affect the type of equipment chosen. For harsh environments, robots with dust-proof and corrosion-resistant features are necessary.

- Maintenance and After-Sales Service: Since painting robots are precision equipment, regular maintenance and prompt after-sales service are crucial. Choosing a reliable brand and supplier ensures the long-term stable operation of the equipment.

Why Should You Invest in Painting Robots?

As a key tool in industrial automation, painting robots not only provide companies with efficient and precise coating solutions but also help them reduce costs and improve competitiveness. With continuous advancements in technology, painting robots will showcase their immense potential across more industries. Understanding the working principles, application scenarios, and advantages of painting robots will help you make more informed decisions when selecting automated coating equipment.

If you are looking for ways to improve production efficiency and product quality, investing in painting robots is undoubtedly your best choice. Selecting the right automated coating equipment will bring your business greater competitiveness and a stronger market advantage.