Everything You Need to Know About Collaborative Robots

Release time: 2025-12-11

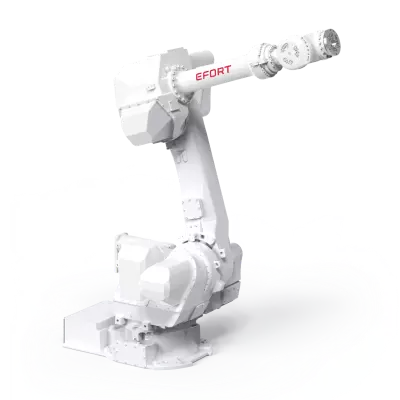

In the current wave of industrial automation, Collaborative Robots (Cobots) are becoming a key technology for manufacturing transformation and upgrading. They are no longer the large, safety-fenced machines of traditional industrial robotics, but rather intelligent partners designed to work safely and in close proximity with human operators in shared workspaces. For businesses looking to increase production flexibility and optimize labor allocation, understanding and deploying collaborative robots is crucial.

What are Collaborative Robots?

Collaborative robots are high-performance robotic arms with built-in intelligent functions that can interact directly and collaborate effectively with humans.

Collaborative Robots VS. Traditional Industrial Robots

| Feature | Collaborative Robots | Traditional Industrial Robots |

| Working Style | Share space and tasks with humans in unfenced areas. | Isolated by safety fences, operating at high speed and power. |

| Safety | Built-in advanced safety features, such as torque limiting, speed monitoring, and safety stops. | Relies on external safety systems (fences, light curtains, etc.). |

| Deployment Difficulty | Simple programming, fast deployment, suitable for multi-task, small-batch production. | Complex programming, time-consuming integration, suitable for repetitive, large-batch production. |

| Return on Investment (ROI) | Lower initial cost, faster return on investment cycle. | Higher initial investment and integration costs. |

The Four Core Safety Collaboration Modes of Cobots

Cobots achieve safe collaboration because they comply with international safety standards like ISO 10218-1 and ISO/TS 15066, utilizing the following four core collaboration modes:

- Safety Monitored Stop:

- The robot immediately stops motion when a human worker enters its operating zone.

- Once the worker leaves the zone, the robot automatically resumes work without needing a restart.

- Hand Guiding:

- The operator directly grips the robot’s end-effector or an attached device to manually teach the robot a path and sequence of movements.

- Commonly used in applications like painting, sanding, or complex trajectory teaching.

- Speed and Separation Monitoring:

- Real-time monitoring of the distance between the worker and the robot using vision systems or sensors.

- As the distance decreases, the robot automatically slows down; if the distance becomes dangerously close, a safety stop is triggered.

- Power and Force Limiting:

- This is the most common collaborative mode. The robot utilizes built-in torque sensors to limit its maximum output force.

- If the robot accidentally makes contact with a worker, it immediately stops or reverses its motion to ensure no harm is caused.

Key Application Areas for Collaborative Robots

Cobots are suitable for a variety of labor-intensive or highly repetitive tasks due to their flexibility, ease of use, and compactness:

- Assembly and Pick-and-Place: Ideal for delicate, repetitive component assembly, and moving parts from trays to the production line.

- Application Advantage: Improves assembly consistency and reduces worker fatigue.

- Machine Tending: Responsible for loading raw materials into CNC machines or injection molding machines, and removing finished products after processing.

- Application Advantage: Increases machine utilization, enabling 24/7 automation.

- Quality Inspection and Packaging: Equipped with vision systems for product defect detection, and automating final packaging and palletizing tasks.

- Application Advantage: Ensures product quality and optimizes logistics efficiency.

- Polishing and Grinding: Handles finishing tasks that require consistent force and trajectory, protecting workers from dust and vibration hazards.

- Application Advantage: Improves the working environment and enhances surface treatment quality.

Core Advantages of Deploying Cobots

1. Flexibility and Agile Production

Cobots are small and easily re-deployed, allowing them to quickly adapt to changes in the production line. This enables manufacturers to easily achieve low-volume, high-mix agile manufacturing.

2. Human-Robot Collaboration, Freeing Up Labor

Cobots take over dull, repetitive, or hazardous jobs, allowing human employees to focus on high-value tasks that require cognitive judgment, creativity, and fine manipulation.

3. Rapid Return on Investment (ROI)

Due to their lower initial costs and simplified integration requirements, Cobots typically achieve ROI within six months to a year and a half, significantly faster than traditional industrial robots.

4. Lowering the Automation Barrier

Cobots commonly use graphical user interfaces (GUI) for drag-and-drop programming. Even non-specialist engineers can quickly learn and deploy them, greatly reducing the technical barrier to automation.

Choose Our Cobot Solutions

Collaborative robots are redefining productivity, enabling factories to be smarter, more flexible, and safer. As your specialized partner, we not only offer industry-leading Cobot products but also provide comprehensive automation consulting, system integration, and after-sales training services.

Choosing our Cobot solutions means choosing:

- Customized End-of-Arm Tooling: Providing high-performance grippers and tools for your specific tasks.

- Rapid Deployment Support: Professional integration teams ensure your Cobots are operational in the shortest time possible.

- Ongoing Technical Training: Ensuring your team can utilize the maximum potential of the Cobots.

Contact Efort today to start your factory’s journey into intelligent collaborative automation!