Everything You Need to Know About SCARA Robots

Release time: 2025-11-28

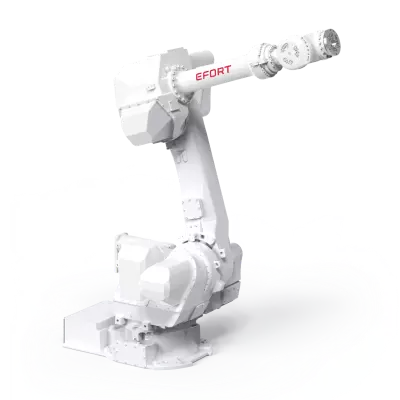

In the modern industrial automation process, SCARA robots have become an essential component in production lines across various industries, thanks to their unique structure and capabilities. As a supplier of SCARA Robotics, Efort is committed to providing high-quality SCARA robot solutions that make production smarter and more efficient. If you’re considering introducing SCARA robots to improve your production efficiency, this article will help you fully understand the core features, application fields, and key considerations when selecting a SCARA robot.

Table of Contents

What is SCARA Robots

SCARA robots (Selective Compliance Assembly Robot Arm) are industrial robots designed for precision assembly and rapid operations. They feature a unique design with four degrees of freedom (2 rotational axes, 1 vertical axis, and 1 rotational axis), offering selective compliance in the horizontal direction while maintaining high rigidity in the vertical direction. This design makes SCARA robots highly effective for high-speed production, precise assembly, and repetitive tasks.

How SCARA Robots Work

A SCARA robot consists of four main components: the base, robotic arm, end effector, and control system. The working principle is as follows:

- Base: Supports the entire robot structure, providing stability.

- Robotic Arm: Made up of multiple rotational joints and bearings, it can rotate in the horizontal plane, allowing for flexible task completion.

- End Effector: Depending on the task, the end effector may be equipped with suction cups, grippers, or welding tools.

- Control System: The robot’s control system allows it to perform preset tasks such as assembly, handling, and inspection.

SCARA robots are highly automated, capable of performing complex tasks within a specified work range with minimal human intervention.

Key Advantages of SCARA Robots

- High Speed and Precision: SCARA robots offer fast movement speeds and high positioning accuracy, making them ideal for applications requiring high-speed operation and precision assembly. Whether handling small electronic components or performing complex assembly tasks, SCARA robots deliver stable, efficient performance.

- Strong Payload Capacity: SCARA robots can be configured to handle different payloads, making them suitable for various production environments, especially in industries such as electronics, automotive, and consumer goods.

- Space Efficiency: Due to their unique design, SCARA robots require less space compared to other types of robots. This makes them ideal for environments with limited space, where efficient use of the available area is essential.

- Low Maintenance Costs: SCARA robots feature a simple yet robust mechanical design, requiring minimal maintenance. They are reliable and have a long lifespan, which reduces the total cost of ownership for companies.

- Flexibility and Customization: SCARA robots can be customized to meet specific application needs, providing greater flexibility. Different end effectors, control systems, and arm lengths can be tailored to perform a variety of tasks, offering a highly adaptable solution.

Applications of SCARA Robots

- Electronics Industry: SCARA robots are widely used in the electronics manufacturing sector for assembly, soldering, and inspection of products such as smartphones, computers, and televisions. Their speed and precision make them well-suited for high-volume production and the precise assembly of small components.

- Automotive Manufacturing: SCARA robots also play a critical role in the automotive industry, where they are used for assembling engine parts, doors, wheels, and other components. Their strong payload capacity and stability are key advantages for automotive production lines.

- Food and Beverage Industry: SCARA robots are used for packaging, sorting, and labeling in the food and beverage industry. Their precise control ensures that packaging quality is maintained while also boosting production efficiency.

- Medical Device Manufacturing: SCARA robots are also employed in the medical device sector for tasks such as assembly and part handling of precision medical instruments. Their high precision, reliability, and efficiency meet the stringent requirements of the medical industry.

- 3C Products Production: SCARA robots are crucial in the production of 3C (computer, communication, and consumer electronics) products. Their ability to maintain high precision at high speeds ensures the quality of every product, especially in fast-paced assembly lines.

How to Choose the Right SCARA Robot

When selecting a SCARA robot, you need to consider the following factors:

- Nature of the Task: Determine the type of task the robot will perform, such as assembly, handling, or welding. Based on the task, select the appropriate SCARA robot model and configuration.

- Payload Requirements: Choose a robot that can handle the weight of the items you need to transport or assemble.

- Working Environment: Consider the specific conditions of your production environment, such as temperature, humidity, and available space, and select a robot that can adapt to these factors.

- Precision Requirements: If high precision is essential for your production process, choose a SCARA robot with high positioning and repeatability accuracy.

- Budget: Select a robot that offers the best value for money within your budget range. Efort provides a wide range of robot models to meet both your budget and performance requirements. Such as ESR10-600Z20,ESR6-500Z20.

Conclusion

SCARA robots play a vital role in modern industrial automation with their efficiency, precision, and flexibility. Whether in electronics manufacturing, automotive production, medical device manufacturing, or food packaging, SCARA robots provide significant improvements in production efficiency and cost savings. As a trusted supplier of SCARA robots, Efort is committed to offering advanced technology and tailored solutions to help your business achieve automation upgrades.

If you are looking for efficient, reliable SCARA robot solutions, feel free to contact us. Efort will provide comprehensive technical support and high-quality products to meet your needs.