Tout ce que vous devez savoir sur les robots de soudage

Release time: 2025-12-31

Welding robots have become a key technology in modern manufacturing for improving efficiency, reducing production costs, and ensuring consistent welding quality. From automotive manufacturing and metal fabrication to electronics production and heavy machinery industries, industrial welding robots play an irreplaceable role in automated welding solutions.

As manufacturing moves toward automation and Industry 4.0, welding robots are now an essential investment for companies seeking higher productivity and long-term competitiveness.

What Is a Welding Robot?

A welding robot is an industrial robot designed to perform automated welding processes through programmed control, sensor feedback, and precise robotic arm motion. It can efficiently complete complex and repetitive welding tasks with high accuracy.

Key features of welding robots include:

✔ High-precision welding performance

✔ High-speed continuous operation

✔ Stable long-term operation

✔ Significantly reduced manual labor

In short, welding robots replace labor-intensive, repetitive, and high-risk welding work, making them a core component of intelligent manufacturing and welding automation systems.

Why Choose Welding Robots? Key Advantages Explained

1. Improved Welding Quality and Consistency

Industrial welding robots maintain stable welding paths and precise parameter control, eliminating human errors caused by fatigue or skill differences. This ensures consistent weld seams, improved strength, and better overall weld appearance.

2. Significantly Higher Production Efficiency

Traditional manual welding limits productivity due to speed and worker fatigue. Welding robots can:

• Operate continuously without interruption

• Increase welding speed and output

• Shorten production cycles

As a result, manufacturers can achieve higher throughput and more stable production capacity.

3. Lower Manufacturing Costs and Higher ROI

Although the initial investment in welding robots may be higher, they offer long-term cost advantages:

✔ Reduced labor costs

✔ Lower rework and defect rates

✔ Shorter production cycles

Over time, welding robots significantly improve return on investment (ROI) and overall production efficiency.

4. Enhanced Workplace Safety

Welding environments involve high temperatures, electric arcs, sparks, and fumes. Welding robots help:

✔ Keep operators away from hazardous conditions

✔ Reduce workplace injuries and safety risks

This makes welding automation a safer and more sustainable solution for modern factories.

Industries and Applications of Welding Robots

Thanks to their flexibility and efficiency, welding robots are widely used across multiple industries:

Fabrication automobile

Welding robots are ideal for car body structures, chassis components, exhaust systems, and other parts requiring high-volume, high-precision welding.

Metal Fabrication

In steel structures and mechanical components, industrial welding robots ensure consistent weld quality and improved production efficiency.

Home Appliance & Electronics Manufacturing

For small weld points and complex welding paths, welding robots provide excellent precision and repeatability.

Heavy Industry

In applications such as construction machinery, shipbuilding, bridges, and large steel structures, welding robots deliver stable performance under heavy-duty working conditions.

How to Choose the Right Welding Robot?

When selecting a welding robot, consider the following key factors:

1. Payload Capacity and Working Range

Choose a robot with suitable load capacity and reach based on workpiece size and welding requirements.

2. Welding Accuracy and Repeatability

High-precision welding applications require robots with rigid mechanical arms and advanced control systems.

3. Control System and Software Compatibility

User-friendly programming, intelligent path planning, and compatibility with mainstream welding power sources improve overall efficiency.

4. After-Sales Service and Technical Support

Reliable suppliers offer complete technical support, spare parts availability, and operator training.

Intelligent Welding Systems: Robot + Peripheral Equipment

A welding robot works best as part of a complete welding automation system, including:

- Welding power sources

- Torque and welding sensors

- Fixtures and tooling systems

- Safety fences and protection systems

- Vision or laser guidance systems for improved positioning accuracy

Integrated systems significantly enhance welding precision, flexibility, and productivity.

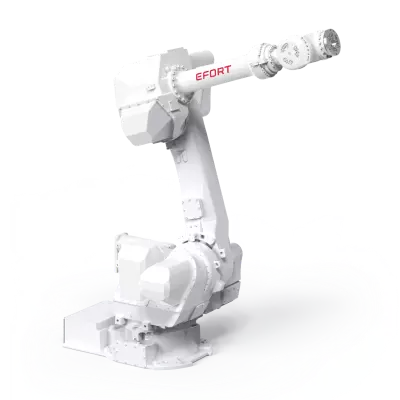

Why Choose EFORT Welding Robots?

EFORT welding robots are designed to meet diverse industrial welding needs and global market standards:

- Multiple models available for different payloads and applications

- Compatible with mainstream welding power sources and control systems

- Professional engineering team providing customized welding solutions

- Rich export experience with global delivery and reliable after-sales support

Welding Robots FAQ

What types of welding tasks are welding robots suitable for?

Welding robots are suitable for tasks such as MIG, TIG, laser welding, and spot welding, and are widely used in the automotive manufacturing and heavy equipment industries.

How do welding robots improve welding quality?

Welding robots provide precise control, reduce human error, and ensure consistent and reliable welding quality.

Can welding robots adapt to different welding materials?

Yes, welding robots can adapt to a variety of welding materials, such as steel, aluminum, and copper, simply by changing the appropriate welding tools and setting the parameters.

What safety measures are required for welding robots?

Sufficient safety protection measures are required during the welding process, such as welding fume extraction systems, fire and explosion prevention devices, etc.

How are welding robots programmed?

Welding robots can be programmed through teach pendant programming, offline programming, or using dedicated programming software to complete task settings.

Whether you are upgrading an existing production line or building a new welding automation system, EFORT welding robots offer a reliable, efficient, and cost-effective solution.