VR software integrated into EPS, VR takes wings, making spraying so simple!

EPS integrates VR functions, enabling fixed-point and tracking VR trajectory teaching, reproduction and operation, and distribution to robots.

No longer use offline software, offline programming, or simulation verification. VR programs can add process and logic control instructions to make their functions more complete.

Maxium payload 180 kg with maxium reach 3160 mm Palletizing Robot Global Supply

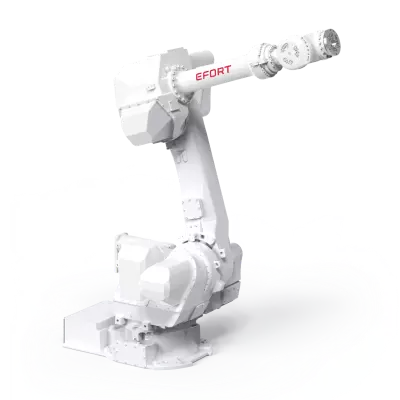

Palletizing Robot ER180-4-3200

- description

- Specifications

- Product structure diagram

-

description

Highlights

Thanks to the excellent stiffness of the robot with sufficient arm span and high-speed intelligent palletization process package,the takt is improved by 15%,

bring customers more efficiency;

Multiple specific application software could be integrated, with soft PLC and a

variety of field bus interface, which enable customers easily face various

application challenges;

High performance collision detection function helps safety realization.

Applications

It can be used in handling operations,palletizing,etc

Industries

Suitable for metal parts, photovoltaic,logistics, cement,food and beverage, and other industries.

-

Specifications

Model ER180-4-3200 Type Articulated

Controlled axes

4 Axes Max. payload on wrist

180 kg Repeatability

±0.1 mm

Robot weight

1350 kg Reach

3160 mm Robot IP grade

IP54 / IP65(Optional)

Cabinet IP grade

IP54

Installation environment

Ambient

temperature

0~45 ℃

Ambient

humidity

RH≤80%(No dew nor frost allowed)

Vibration

acceleration

4.9 m/s²(<0.5 G)

Drive mode

AC servo drive

Installation

Floor

Allowable load

moment at wrist

J4 190 N·m Allowable load

inertia at wrist

J4 56.6 kg·m² Maximum speed

J1 104°/ sec

J2 104°/ sec

J3 104°/ sec

J4 210°/ sec

Motion range

J1 ±180°

J2 +40°/-86°

J3 +60°/-52°

J4 ±360° J2+J3 -106°≤(J2+J3)≤+20°

-

Product structure diagram